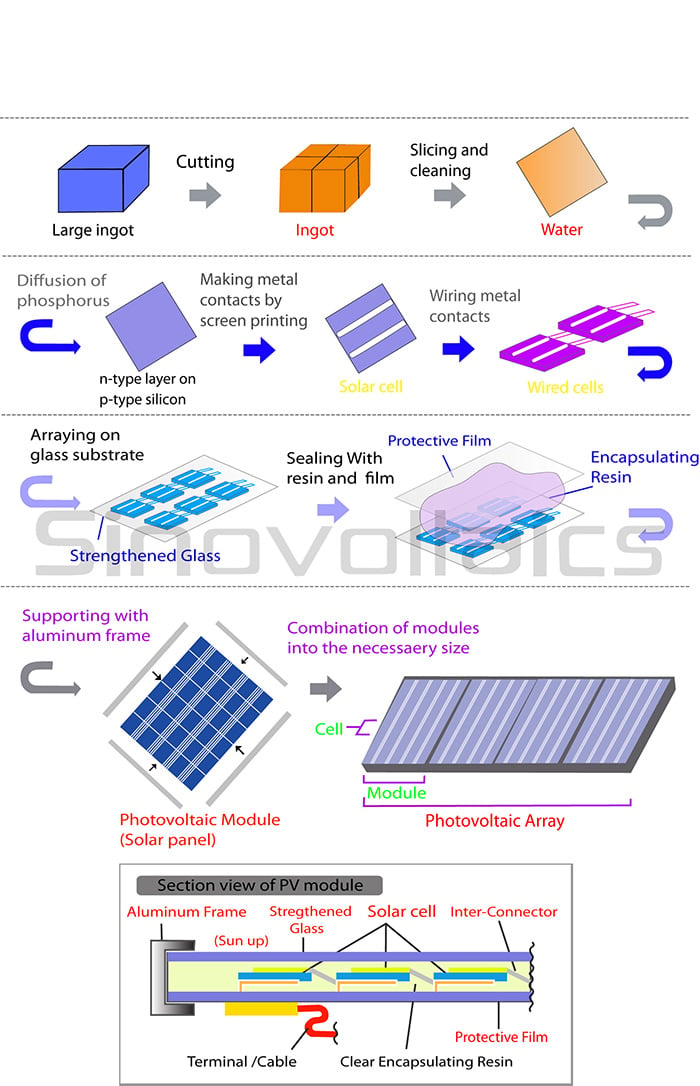

The solar module manifacturing process starts already from the choice of materials with the use of machines for cutting the rolls of encapsulant and bachksheet.

Solar panel manufacturing process steps.

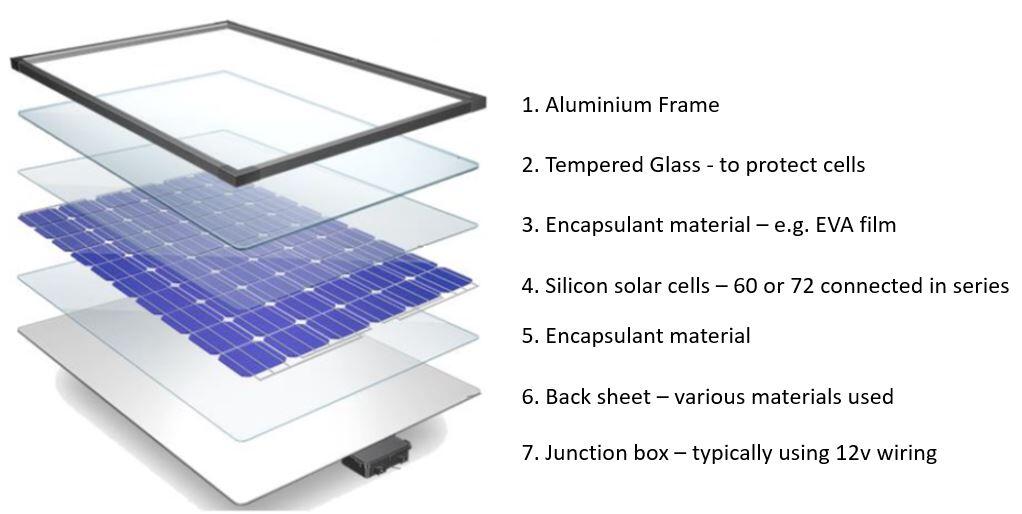

In this step solar panels are made from solar cells by thin electric connections in between them electrical connections are made in series to achieve a desired output voltage and or in parallel to provide a desired current capability.

The conducting wires that take the current off the modules may contain silver copper or other non magnetic conductive transition metals.

Read below about the steps of producing a crystalline solar panel.

The first step in making a solar panel is to mine and purify silicon.

In fact it s the second most abundant element right behind oxygen on the planet.

Draft your business plan.

The products are carbon dioxide and molten silicon.

The next step in the solar panel manufacturing process is lamination.

These 7 steps would come in handy as you start your own solar panel manufacturing company from any part of the world and still gain global market acceptance.

A carbon arc is then applied to release the oxygen.

The silicon used to make the vast majority of today s photovoltaic cells is abundant but a silicon based solar cell requires a lot of energy input in its manufacturing process said.

Three main steps to manufacture the solar panel 4 1 get the conductive glass ready put titanium dioxide powder and binder slowly coated on the tempered glass burn up and then cool down.

Thin film solar panels.

After thet the lacing the arrangement of the glass the welding of the heads through a ribbon done manually in the standard lines the preparation for the lamination and the test and then the proper rolling process the framing and the j box application.

Thus at cell structure level there are different types of material for manufacturing such as mono silicon polysilicon or amorphous silicon ansi.

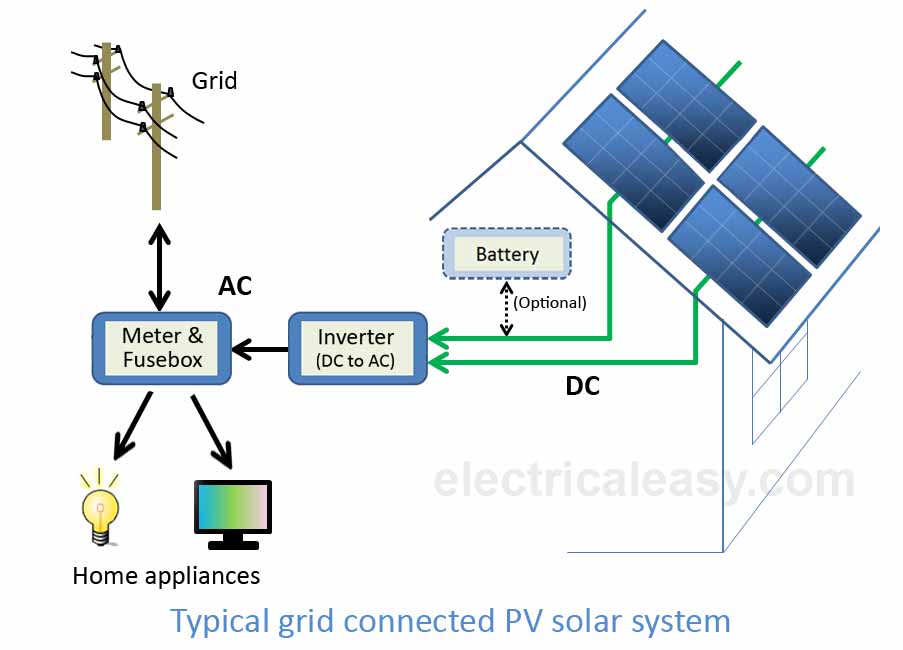

Solar panel manufacturing process after having produced the solar cells and placed the electrical contacts between the cells they are then wired and subsequently arrayed.

During lay up solar cells are stringed and placed between sheets of eva.

The manufacturing process purifying the silicon 1 the silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace.

Starting a solar panel manufacturing company sample business plan template.

Purification is usually done with an electric furnace.

The first 2 kinds of cells have a somewhat similar manufacturing process.