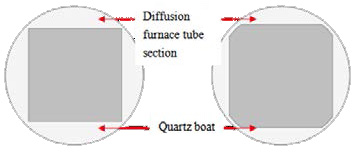

In electronics a wafer also called a slice or substrate is a thin slice of semiconductor such as a crystalline silicon c si used for the fabrication of integrated circuits and in photovoltaics to manufacture solar cells the wafer serves as the substrate for microelectronic devices built in and upon the wafer.

Solar cell wafer size.

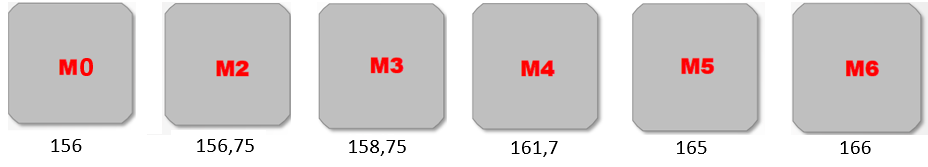

At that time our taiwanese cell manufacturer went straight from m2 to the m4 with a size of 161 7 mm in order to only make necessary investment purchases once together with the multi busbar variant.

Tim to 2019 m6 166mm x 166mm p type mono wafers 223mm diameter silicon ingot was lauched.

Changing the wafer size and moving to half cut cells was seen as the best option to get to 400wp.

During 2018 to 2019 g1 square wafer 158 75mmx158 75mm was inaugurated to the market and adopted by some solar cell manufacturers.

However leading mono wafer producer longi green energy technology and major merchant solar cell producers aiko solar and tongwei group started offering 161 75mm x 161 75mm.

At the end of q3 2019 longi solar the world s largest mono wafer manufacturer launched another variant on the market for the first time.

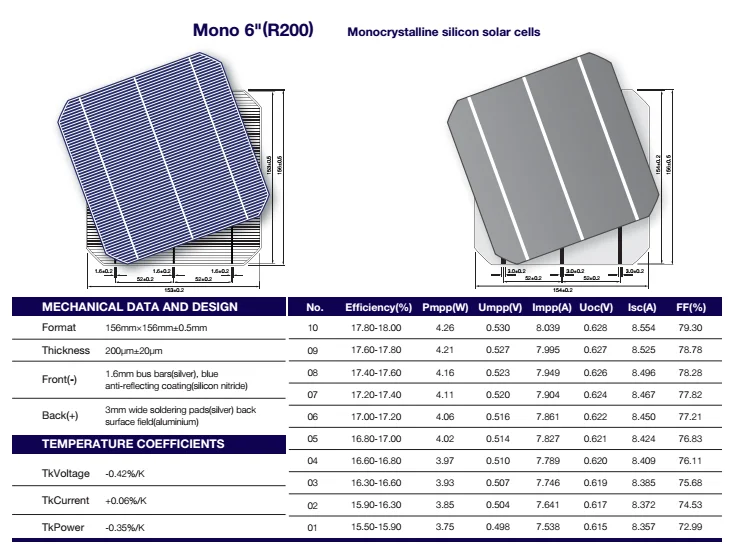

Multiple solar cells in an integrated group all oriented in one plane constitute a solar photovoltaic panel or module photovoltaic modules often have a sheet of glass on the sun facing side allowing light to pass while protecting the semiconductor wafers solar cells are usually connected in series creating additive voltage and current.

However several manufacturers had their own ideas on what the larger wafer size should be such.

Connecting cells in parallel yields a higher current.